Understanding Cost Reduction Consulting

In a world where businesses grapple with inflation, supply chain disruptions, and labor shortages, cost management has become more critical than ever. Cost reduction consultants are specialized professionals who help companies uncover unnecessary expenditures, improve process efficiency, and renegotiate vendor contracts to save money—often millions over time.

These experts take a data-driven, results-oriented approach, ensuring that cost savings don’t come at the expense of quality, employee morale, or long-term growth. Rather than sweeping layoffs or slashing budgets arbitrarily, their methods are strategic, sustainable, and aligned with business goals.

How Do Cost Reduction Consultants Work?

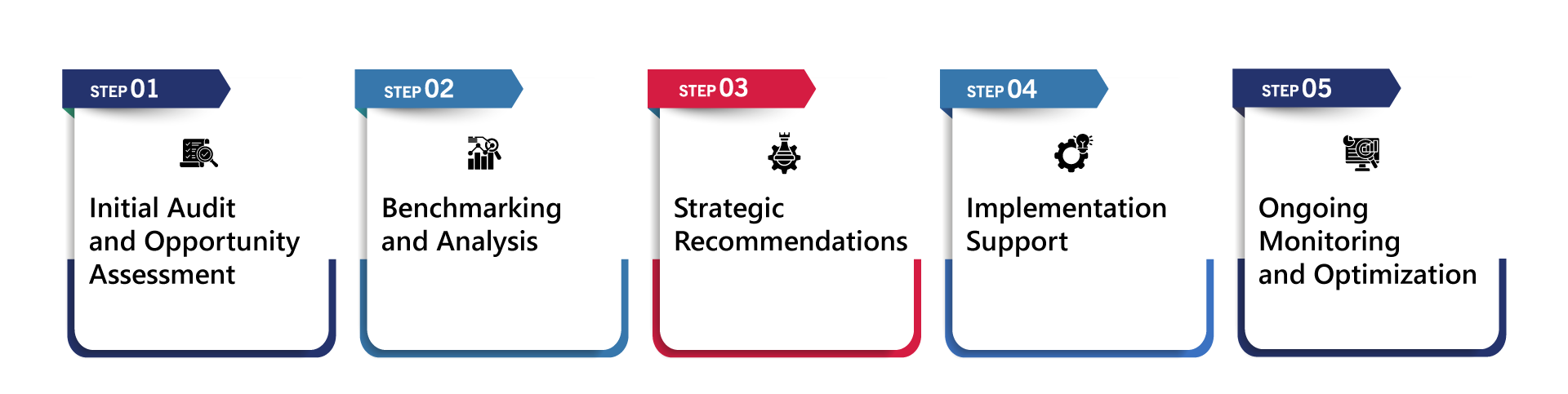

Step-by-Step Process

- Initial Audit and Opportunity Assessment

Consultants begin with a thorough audit of your business’s expenses, including procurement, operations, logistics, HR, IT, utilities, and more. This initial discovery phase helps them identify potential savings areas. - Benchmarking and Analysis

Your expenses are benchmarked against industry standards and historical data. Cost reduction consultants use proprietary tools, market knowledge, and vendor databases to spot inefficiencies. - Strategic Recommendations

Based on findings, consultants provide tailored recommendations—from renegotiating supplier contracts to adopting more efficient technology or altering procurement strategies. - Implementation Support

The best Cost reduction consultants don’t stop at advising. They implement the changes, monitor progress, and train internal teams to ensure long-term compliance. - Ongoing Monitoring and Optimization

Savings are tracked, KPIs are monitored, and processes are continually improved to maintain the achieved cost reductions.

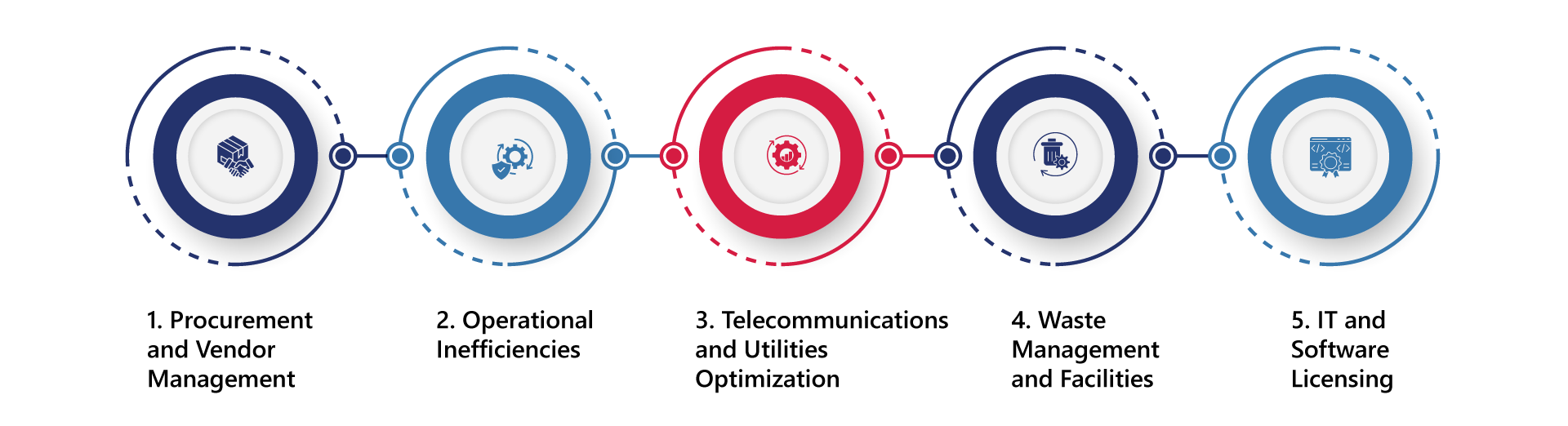

Key Areas Where Consultants Save Money

1. Procurement and Vendor Management

Vendors are often a top source of unnecessary spending. Cost reduction consultants examine your entire supplier base and:

- Negotiate better rates using volume-based leverage or alternate sourcing.

- Consolidate vendors to simplify logistics and reduce redundancies.

- Introduce competitive bidding to get the best value.

2. Operational Inefficiencies

Operational bottlenecks, outdated processes, and manual systems can significantly drain resources. Consultants conduct time-motion studies and workflow mapping to:

- Eliminate redundant steps.

- Automate manual processes using low-code or RPA tools.

- Improve team productivity with lean methodologies.

3. Telecommunications and Utilities Optimization

Telecom and energy expenses are often mismanaged due to complexity and lack of visibility. Consultants analyze:

- Line usage and redundant services

- Energy consumption patterns

- Contract compliance

They often uncover unused lines, misbilled charges, or opportunities for energy-efficient upgrades.

4. Waste Management and Facilities

Most companies overlook savings in waste disposal, janitorial services, and office leases. Consultants assess:

- Pickup schedules

- Waste sorting strategies

- Space utilization

And propose renegotiations or changes to more sustainable, cost-effective solutions.

5. IT and Software Licensing

Technology costs can skyrocket without careful oversight. Consultants evaluate:

- SaaS usage and subscription tiers

- Licensing overlaps

- Cloud spend

They help consolidate platforms, optimize storage costs, and cancel unused tools.

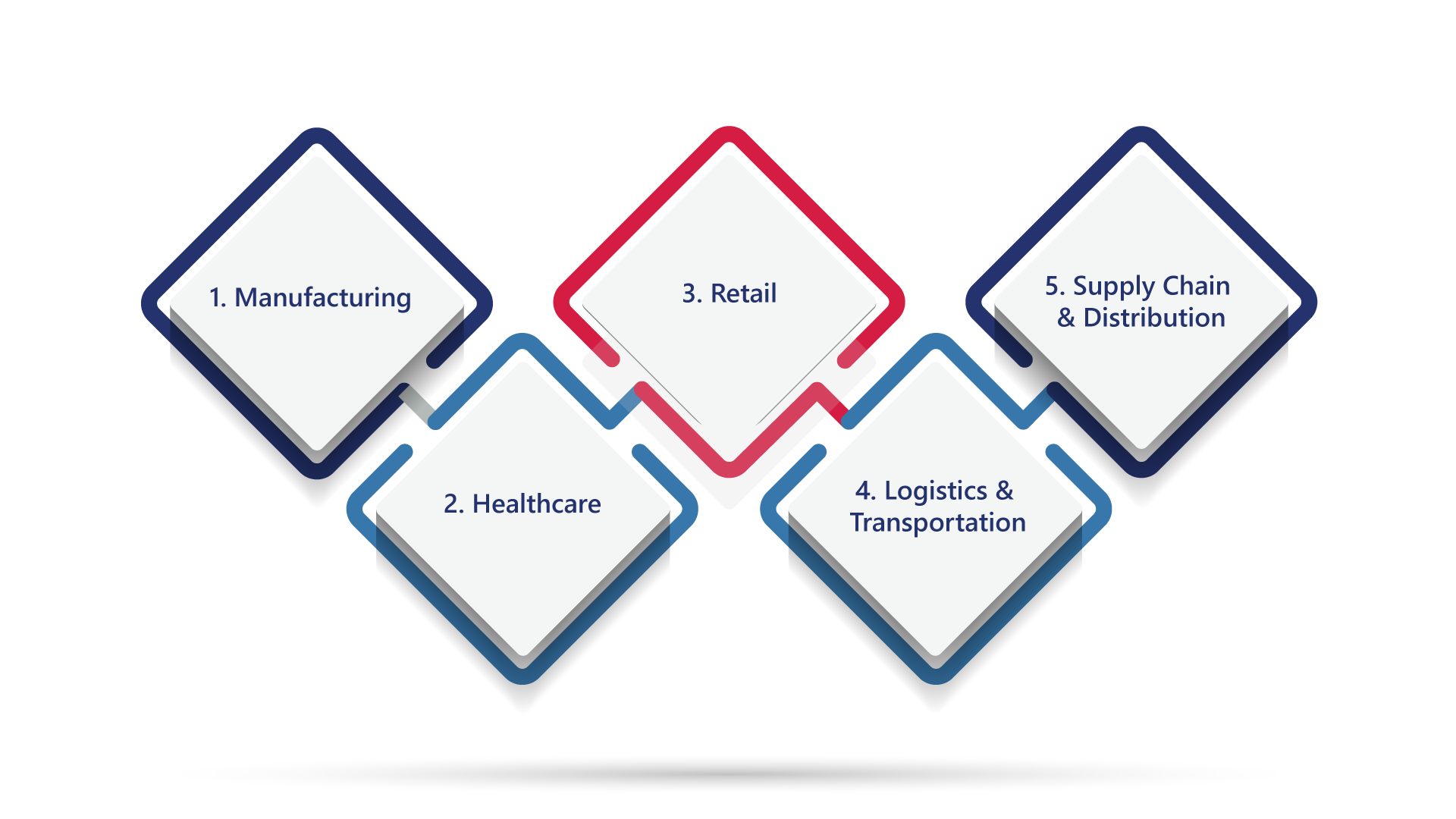

Industries That Benefit the Most

While virtually any organization can benefit from a cost reduction consultant’s expertise, certain industries experience more significant and immediate ROI due to the scale and complexity of their operations. Here’s how some of the most impacted industries benefit:

1. Manufacturing

Key Savings Achieved with CCO:

- Reduced downtime through lean process optimization and predictive maintenance. CCO implements lean methodologies such as value stream mapping and 5S to eliminate process waste and identify delays. Predictive maintenance tools are introduced to monitor equipment health in real time, minimizing unexpected breakdowns and production halts.

- Lower labor costs from better workforce scheduling and cross-training. By analyzing production schedules, shift patterns, and output variance, CCO creates smarter labor models that reduce overtime and idle time. Cross-training programs are implemented to create a more flexible workforce, reducing reliance on temporary staff.

- Waste reduction using root cause analysis and standardized procedures. CCO uses Six Sigma tools (like DMAIC and fishbone diagrams) to isolate the sources of scrap, defects, or process inefficiencies. They standardize work instructions across shifts to ensure consistency and quality, significantly lowering material and rework costs.

- Increased throughput without capital investment through improved line balancing and takt time tracking. Rather than recommending costly equipment upgrades, CCO adjusts line balance based on takt time (customer demand rate) to optimize flow and eliminate bottlenecks. This maximizes output with existing assets.

Why It Matters:

Manufacturing is capital-intensive. Cost reduction consultants like CCO deliver productivity gains and free up working capital for innovation.

2. Healthcare

Key Savings Achieved with CCO:

- Staffing cost reductions via improved shift planning and fewer agency hires. Using real-time data on patient volume and acuity, CCO helps hospitals build dynamic staffing models that reduce overtime, minimize agency dependency, and better align clinician availability with patient needs.

- Increased patient throughput by reducing bottlenecks in admissions and discharge. Through process mapping and queuing analysis, CCO identifies pain points in patient movement. Streamlined protocols are introduced to reduce emergency department wait times, accelerate discharges, and optimize bed turnover rates.

- Supply chain savings through procurement standardization and reduced SKU variability. By consolidating vendors, reducing item variation, and aligning with group purchasing organizations (GPOs), CCO helps lower acquisition costs and simplify inventory management.

- Revenue optimization via cleaner billing, reduced denials, and better documentation. CCO enhances charge capture by streamlining clinical documentation workflows and integrating automation into billing and coding systems—ensuring fewer missed charges and faster reimbursement.

Why It Matters:

Healthcare systems face strict compliance mandates and thin margins. CCO delivers savings that preserve quality of care while reducing unnecessary spend and boosting operational agility.

3. Retail

Key Savings Achieved with CCO:

- Labor cost reduction via improved scheduling, sales forecasting, and productivity standards. CCO introduces labor management systems that align staffing levels with foot traffic and seasonal trends. They develop productivity KPIs that optimize team deployment and prevent overstaffing.

- Inventory shrink and stockout prevention using predictive analytics and real-time dashboards. Advanced demand forecasting tools reduce inventory loss and out-of-stocks by ensuring accurate replenishment cycles. Real-time dashboards give store managers visibility into product movement and shrinkage trends.

- Lower logistics spend through smarter fulfillment methods and last-mile delivery optimization. By analyzing transportation spend, delivery windows, and warehousing strategies, CCO optimizes omnichannel fulfillment models—reducing courier costs, improving delivery speed, and eliminating split shipments.

- Accelerated store openings with streamlined project planning and contractor coordination CCO applies lean project management techniques to ensure faster execution of store builds, remodels, or relocations—eliminating costly delays and improving ROI on new locations.

Why It Matters:

Retail thrives on margin and volume. A cost reduction consultant helps optimize every moving part—without hurting the customer experience.

4. Logistics & Transportation

Key Savings Achieved with CCO:

- Fuel and delivery cost savings through advanced route and mode optimization

CCO analyzes route data to consolidate loads, minimize empty miles, and shift to more efficient carriers or transport modes (e.g., rail vs. truck). Real-time GPS and TMS (transportation management systems) are used to streamline delivery scheduling.

- Overtime reduction via shift redesign and dock-to-stock efficiency using time-and-motion studies, CCO reconfigures labor models to reduce shift overlap and improve loading/unloading efficiency. They standardize dock workflows and reduce idle time, cutting overtime costs significantly.

- Improved space utilization by redesigning warehouse layouts and shelving

CCO redesigns warehouse zones using ABC inventory analysis and vertical space optimization. These changes reduce travel time for pickers and create additional capacity without facility expansion.

- Cycle time reduction using standardized processes and automation in fulfillment

CCO introduces WMS upgrades, barcode scanning, and autonomous mobile robots (AMRs) where appropriate. These tools streamline picking, packing, and shipping processes—accelerating order fulfillment.

Why It Matters:

Transportation and logistics firms operate under enormous cost pressure. CCO enhances operational efficiency without sacrificing service reliability or compliance.

5. Supply Chain & Distribution

Key Savings Achieved with CCO:

- Excess inventory and stockout reduction through end-to-end visibility

CCO connects planning, procurement, and fulfillment systems to create a unified view of inventory across nodes. This real-time insight prevents overordering and helps reallocate stock dynamically across channels.

- Lower sourcing costs from vendor consolidation and market re-bidding

By reducing the number of suppliers and initiating competitive sourcing events, CCO helps companies negotiate better terms, lower unit costs, and introduce alternate sourcing strategies.

- Transportation savings via mode mix improvements and carrier negotiations CCO evaluates freight cost structures and carrier contracts. They negotiate new terms, consolidate shipments, and adjust delivery methods to balance cost, speed, and reliability.

- Faster order fulfillment through cycle time reduction and better planning Integrated sales and operations planning (S&OP) processes are established to align demand forecasts with production and distribution. CCO cuts down fulfillment lead times and increases service levels without inflating inventory.

Why It Matters:

In supply chains, visibility and coordination are king. CCO helps companies transition from reactive to proactive supply chain management—turning logistics into a competitive advantage.

Why Companies Overlook These Opportunities

Many businesses believe they’ve already optimized costs—when in reality, they’ve only scratched the surface. Some common reasons for missed opportunities include:

- Internal Bias: Teams often accept legacy vendors or processes as the norm.

- Lack of Expertise: Procurement, finance, and operations staff may lack negotiation expertise.

- Limited Time: Cost reviews are postponed due to other priorities.

- Fear of Disruption: Businesses avoid changes fearing it may affect service delivery.

Cost reduction consultants offer objectivity, tools, and specialized knowledge to cut through these barriers.

Cost vs. Value: Is It Worth Hiring a Consultant?

Most cost reduction consultants work on a performance-based model—they’re compensated based on the savings they generate. This structure:

- Minimizes risk for the client

- Aligns the consultant’s success with yours

- Ensures maximum effort and transparency

Return on Investment (ROI):

Clients typically see an ROI of 3x to 10x within the first year of engagement. For example, investing $50,000 in consulting could easily translate to $500,000 in annual savings.

Common Myths Debunked

- “They just cut jobs.”

False. Most savings come from smarter spending, not layoffs. - “Consultants are too expensive.”

Not when they’re paid on performance. You pay only when you save. - “We already reviewed our costs.”

Consultants use benchmarks, tools, and strategies most businesses lack. - “They disrupt operations.”

A good consultant works in the background, ensuring business continuity.

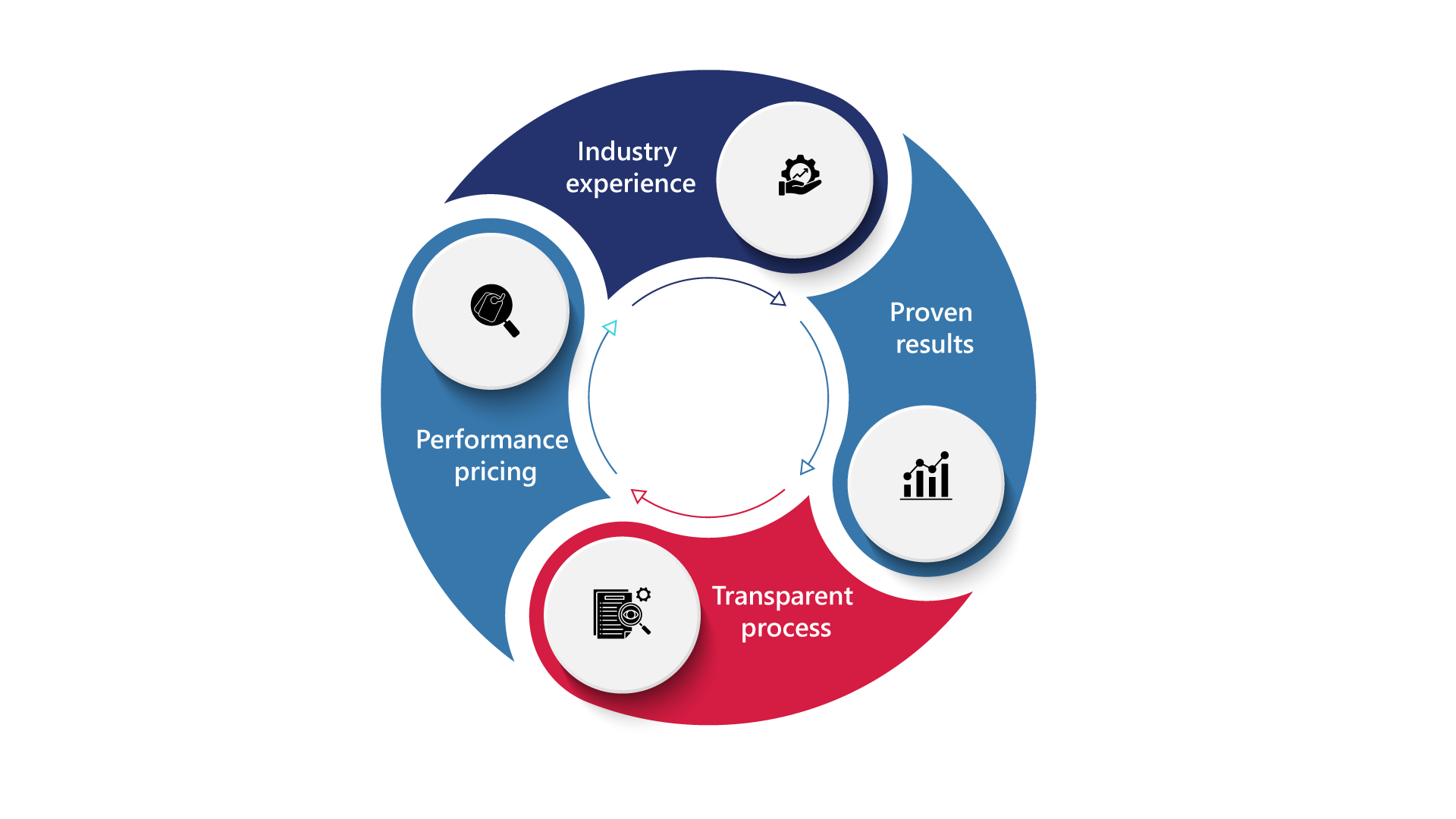

Choosing the Right Partner

Look for a cost reduction consulting firm with:

- Industry experience: Do they know your market dynamics?

- Proven results: Can they show past successes and client testimonials?

- Transparent process: Do they explain how they calculate savings?

- Performance pricing: Are they willing to stake their fee on results?

Why CCO Consulting Stands Out

At CCO, the approach is simple but effective:

- Customized strategies: Every business is unique; solutions are tailored.

- Hands-on implementation: CCO doesn’t just advise—they execute.

- Performance-based pricing: You only pay when you save.

- Long-term partnerships: Beyond quick wins, they build systems for continued savings.

Whether you’re a startup scaling quickly or a legacy enterprise trying to rein in costs, CCO can guide you to smarter, more sustainable spending.

Final Thoughts

In today’s competitive and uncertain business environment, cost efficiency is no longer optional—it’s essential. Cost reduction consultants provide the expertise, objectivity, and actionable strategies companies need to uncover hidden savings and redirect resources to growth.

The right consulting partner doesn’t just cut costs—they fuel profitability, resilience, and long-term success. And firms like CCO Consulting are leading the way.