Optimizing Logistics in the Retail Industry with Supply Chain Management Consulting

In today’s omnichannel and fast-paced retail environment, logistics plays a pivotal role in ensuring the right products are delivered to the right place at the right time—efficiently and cost-effectively. With increasing consumer expectations for faster deliveries, real-time tracking, and personalized shopping experiences, retailers must evolve their logistics strategy consulting to remain competitive.

In this guide, we explore the current challenges in retail logistics optimization and how businesses can optimize operations using technology, smarter inventory management in retail, and innovative last-mile delivery solutions. We’ll also highlight real-world success stories to illustrate what excellence in supply chain management consulting looks like.

Understanding the Current Challenges in Retail Logistics

Retailers face a complex web of logistical challenges driven by shifting consumer behavior, global supply chain disruptions, and pressure to operate more sustainably.

● Omnichannel Complexity

Modern consumers shop across multiple touchpoints—e-commerce websites, mobile apps, in-store kiosks, and social platforms. Retailers must integrate inventory and fulfillment across all channels to meet demand seamlessly. This requires tight coordination between warehousing, transportation, and customer service systems.

● Demand Volatility

Sales spikes during holiday seasons, promotional campaigns, or viral trends can create massive strain on logistics systems. Failing to anticipate demand fluctuations often leads to out-of-stocks, overstocking, or missed delivery windows.

● Supply Chain Disruptions

From raw material shortages to international shipping delays, global disruptions can paralyze inventory flows. Events like the COVID-19 pandemic and the Russia-Ukraine conflict have exposed vulnerabilities in overly centralized or rigid supply chains.

● Rising Costs

Transportation fuel, labor, warehousing rent, and packaging expenses are rising. Meanwhile, customer expectations for free shipping and next-day delivery are higher than ever, squeezing profit margins.

● Sustainability Pressures

Consumers and regulators are calling for greener logistics. This means reducing carbon emissions, minimizing packaging waste, and optimizing delivery routes to reduce fuel usage.

Overcoming these challenges requires a blend of real-time data, advanced technology, flexible operations, and a customer-centric mindset.

Smarter Inventory Management and Demand Forecasting in Retail

Efficient inventory management in retail is the cornerstone of retail logistics optimization. Retailers must strike the right balance between availability and cost while avoiding overstocks and stockouts.

● AI-Powered Forecasting

Modern retailers use AI in supply chain management to analyze historical sales, seasonal trends, and external factors like weather, local events, and social media sentiment. This helps generate more accurate demand forecasts by product, store, and region.

For instance, a fashion retailer can use AI to predict which sizes and styles will be in demand across regions, avoiding dead stock and missed sales.

● Just-In-Time Inventory

JIT models help minimize inventory holding costs by syncing replenishment with real-time sales data. While effective, it requires tight supplier coordination and real-time visibility.

● Dynamic Replenishment

Retailers can implement systems that automatically adjust replenishment orders based on current inventory levels, demand patterns, and transit lead times. This is especially useful for fast-moving consumer goods (FMCG).

● Safety Stock Optimization

Instead of one-size-fits-all buffers, retailers use SKU-level risk modeling to determine optimal safety stock, improving service levels without excessive stockpiling.

Through smarter forecasting and supply chain management consulting, retailers can reduce carrying costs, improve turnover rates, and ensure product availability.

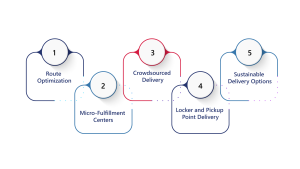

Innovative Last-Mile Delivery Solutions for Retailers

Last-mile delivery solutions—the final step of the logistics journey to the customer—is often the most expensive and complex component of retail logistics.

● Route Optimization

AI and geospatial data are used to calculate the fastest and most fuel-efficient delivery routes. These tools factor in real-time traffic, weather, and delivery time windows to minimize delays and costs.

● Micro-Fulfillment Centers

Retailers are decentralizing fulfillment by setting up smaller distribution hubs closer to urban centers. These micro-fulfillment centers reduce delivery time and cost, and can be set up within existing retail spaces.

● Crowdsourced Delivery

Platforms like Uber, DoorDash, and Postmates offer flexible last-mile delivery solutions by tapping into gig workers. This model improves scalability during peak times.

● Locker and Pickup Point Delivery

Retailers like Amazon and Walmart are using lockers and pickup points to consolidate last-mile efforts. Customers benefit from convenient access, while retailers reduce failed delivery attempts and costs.

● Sustainable Delivery Options

Electric vehicles, bike couriers, and carbon-neutral shipping programs are being adopted to meet environmental goals and appeal to eco-conscious customers.

A well-executed last-mile strategy enhances customer satisfaction, builds loyalty, and reduces delivery costs—key to long-term success in e-commerce and omnichannel retail.

Integrating Technology for End-to-End Supply Chain Visibility

Real-time visibility is no longer optional—it’s a strategic advantage. Retailers need end-to-end insight into inventory, shipments, and supplier performance to proactively manage disruptions and meet service commitments.

● ERP and WMS Integration

Enterprise Resource Planning (ERP) and Warehouse Management Systems (WMS) integrate data from procurement, inventory, sales, and operations consulting firms’ processes. This helps retailers manage orders efficiently and forecast inventory requirements accurately.

● IoT Sensors

Internet of Things (IoT) devices track the condition and location of goods throughout the supply chain. This is especially useful for perishables and high-value items. Retailers can monitor temperature, humidity, and motion to prevent damage or spoilage.

● Blockchain for Traceability

Blockchain enables secure, tamper-proof tracking of goods across the supply chain. It improves trust with consumers by providing transparent origin and journey data—useful for ethically sourced or organic products.

● Cloud-Based Logistics Platforms

Centralized platforms aggregate data from suppliers, carriers, and fulfillment centers, providing real-time dashboards and alerts. This allows retailers to make informed decisions quickly during disruptions or demand spikes.

● Analytics and Reporting

Advanced analytics platforms help measure KPIs like on-time delivery rate, order accuracy, inventory turnover, and logistics costs. Retailers can identify bottlenecks, forecast performance, and continuously improve operations.

By leveraging the right mix of digital tools, retailers can transform logistics from a cost center into a competitive differentiator.

Case Studies: Retail Logistics Success Stories from Leading Brands

● Zara – Agile Inventory Model

Zara’s logistics model is built for speed and flexibility. Using data from stores and e-commerce, the brand can adjust its production and inventory weekly. Its central distribution centers can ship new items to stores worldwide in just 24-48 hours. This rapid turnaround reduces overstock and keeps the brand aligned with fashion trends.

● Amazon – Robotics and Automation

Amazon’s fulfillment centers use a combination of AI, machine learning, and over 500,000 robots to automate picking, packing, and sorting. Combined with their own transportation fleet and real-time tracking systems, Amazon delivers millions of orders daily with high accuracy and speed.

● Walmart – Integrated Omni-Fulfillment

Walmart has invested heavily in omnichannel logistics by converting stores into local fulfillment hubs. Through curbside pickup, home delivery, and smart inventory replenishment, the retail giant has boosted delivery speed while reducing operational costs.

● Nike – Direct-to-Consumer Shift

Nike overhauled its logistics by opening new distribution centers and using predictive analytics for demand planning. Its Consumer Direct Acceleration strategy enabled faster order processing and personalized delivery experiences, increasing customer satisfaction and reducing returns.

These success stories underscore the importance of aligning logistics with customer expectations, business strategy, and digital innovation.

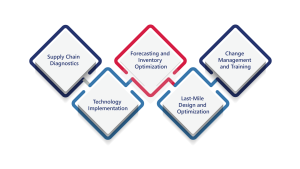

CCO Consulting: Powering Logistics Excellence for Retail Businesses

At CCO Consulting, we empower retailers to evolve their logistics through expert supply chain management consulting, process transformation, and digital innovation. Our services include:

- Supply Chain Diagnostics: We assess current logistics performance, identify inefficiencies, and develop roadmap strategies.

- Technology Implementation: From warehouse automation to ERP integration, we support your digital logistics transformation.

- Forecasting and Inventory Optimization: Using advanced analytics, we fine-tune your demand and replenishment strategies.

- Last-Mile Design and Optimization: We design scalable, customer-centric delivery models that improve margins and satisfaction.

- Change Management and Training: We ensure teams are aligned, trained, and empowered to sustain improvements.

Whether you’re a growing e-commerce brand or a national retailer, our expertise helps you deliver on your promise—every time.

Conclusion: Transforming Retail Logistics for a Customer-First Future

Retail logistics is no longer just about moving products—it’s about delivering experiences. In this era of hyper-connected consumers and volatile supply chains, strategy consulting firms and business operations consulting firms that embrace agility, visibility, and innovation will lead.

We’ve explored today’s pressing logistics challenges and shown how operational excellence consulting firms can help retailers overcome them with smarter inventory, agile last-mile delivery solutions, and real-world execution.

To unlock the full potential of your logistics operations, partner with CCO Consulting—where strategy meets execution.